A petrol fuel system is a critical component of a car. This type of internal combustion engine runs on a fuel that is highly volatile. The following article explains the main components and their functions. It also covers the water separation media and pump. After reading this article, you should be able to make a good decision regarding your vehicle’s petrol fuel system. Here are some important points to remember:

Common components

Your car’s fuel system contains several parts, including the gas tank, the fuel pump, the air filter, and the fuel injector. Fuel lines connect these parts to the engine. These parts all perform important roles in the proper operation of your car. In general, these parts do not fail due to harsh weather conditions, but can be damaged by rust. Listed below are the basic components of a petrol fuel system.

The tank stores your fuel and helps to maintain it below the flash point. It also serves as a heat dissipation device. Your fuel tank should be corrosion-resistant and leakproof to prevent excessive gas waste. It should also have a mechanism for stopping excessive pressure buildup. When inspecting your vehicle’s fuel tank, you should also check if it is leaking. If it is, it may need to be replaced.

Functions

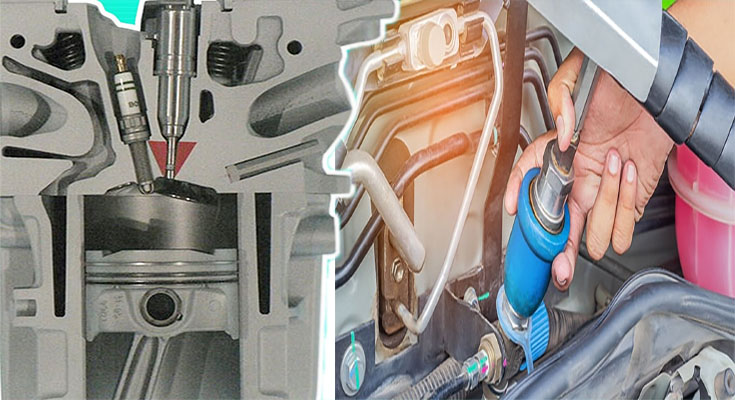

The basic parts of a car’s fuel system include the gas tank and the fuel pump. These parts work together to store fuel and deliver it to the engine, where it is mixed with air to produce energy. Different cars use different systems, but they all have the same basic function: to deliver the proper amount of fuel to the engine. The fuel system also controls the proportion of fuel and air to the combustion chamber. The following sections will explain the various components of a petrol fuel system and provide a basic overview of their functions.

The fuel pump delivers fuel to the injectors, and the pressure regulator maintains a constant pressure within the system. The fuel lines, meanwhile, deliver the fuel to different parts of the fuel system, including the cylinders. The regulator controls the pressures and returns excess fuel to the fuel tank. The PCM monitors the fuel level, and the system compensates for any variations in the pressure. The PCM also monitors the pressure in the fuel system, and is responsible for regulating the flow of fuel.

Water separation media

The selection of water separation media in a petrol fuel system depends on the environment in which the vehicle is used. Vehicles used in moderate environments may not require a water separator. However, vehicles operating in extreme conditions should install one. Such environments can result in excessive dirt and debris entering the fuel storage system. In such cases, contaminated fuel can result in reduced performance. To avoid this problem, fuel systems should be designed to separate water before it enters the engine.

There are two main methods for separating water from petrol fuel systems. Firstly, water is separated by changing the direction of flow. This method is commonly combined with gravity, which does not work on very small droplets. The other way is to use a centrifuge, which separates water by reducing the fuel flow velocity. It is important to remember that water is much denser than petrol. If you are planning to use a centrifuge to separate water, make sure it is made from a material that has good coalescing properties.

Pump

A fuel pump is a mechanical component that transports petrol, diesel, or other types of fuel. Some pumps are electric, and are usually installed in cars with fuel injection systems. These pumps generate high pressures that can ignite the gasoline within the pump, leading to an explosion. Therefore, they should be located away from the engine, and preferably in the fuel tank. Some types of pumps also have a hydraulic outlet. Regardless of the type of pump, you should have a basic knowledge of the types of pumps available for your vehicle.

A fuel pump is typically powered by the battery in your car. It has an electronic control module that regulates the volume and output pressure of gasoline. The pump also has a sensor that measures the temperature of the fuel rail. This data is displayed on a scan tool. The pump operates by sending a pulse width modulated (PWM) signal to the control module. A pump control module is designed to improve fuel economy and power.

Carburetor

A car’s petrol fuel system contains a carburetor. This device mixes air with fuel to produce a mixture for combustion. The two-chamber carburetor works with a venturi that creates a pressure differential between the air and mixture. Unlike a traditional carburetor, the air and mixture enter the bottom chamber and exit the top chamber. The air and mixture then pass through the mixing chamber, where the float and jet are located.

Nowadays, fuel injection is used to replace carburetors. It is more efficient and gives precise air-to-fuel ratios. However, it is more expensive and complex to fix than carburetors. To identify whether a car has fuel injection, check the fuel lines in the engine compartment. They are usually metal pipes connecting each cylinder. If the fuel lines are connected to a round box, it has a carburetor.

High pressure pump

A high pressure pump for petrol fuel system has several important functions. Incorrect operation can reduce fuel efficiency and shorten engine life. Improper operation of a high pressure pump can result in off-key injection timing which can damage a catalytic converter. This article will explain how high pressure pumps work. It also offers some maintenance tips for your pump. After reading this article, you should be able to identify the symptoms of a malfunctioning pump in your vehicle.

Unlike a normal fuel pump, a high pressure pump is not required to maintain a specific fuel pressure. This pressure is determined by your engine’s capacity. Cars with carbureted engines often require less than four pounds of pressure, while higher-performance engines require up to 60 pounds of pressure. Higher pressures will increase horsepower, but aftermarket fuel pressure regulators may not be enough to maintain the desired pressure.