Achieving Efficiency Through Automation in Electric Vehicle Assembly

As the demand for electric vehicles (EVs) continues to rise, manufacturers are constantly seeking ways to optimize the assembly process for efficiency. One of the key strategies that has proven to be highly effective is the integration of automation technologies. Automation in the electric vehicle assembly process not only streamlines production but also improves quality, reduces lead times, and minimizes overall costs.

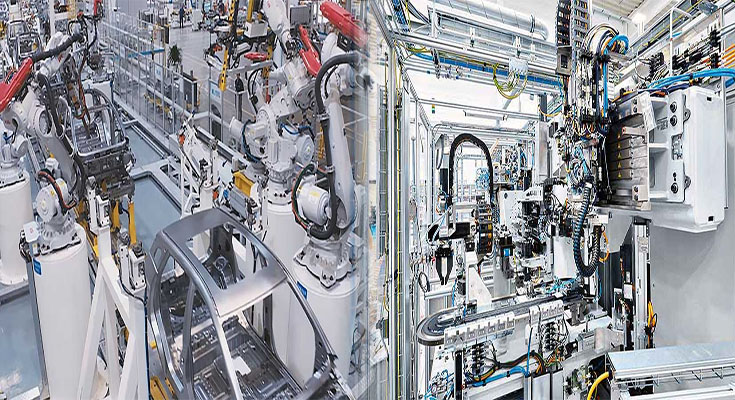

Streamlining Production with Robotics

Robotic systems are integral to automation in the electric vehicle assembly process. These systems can perform a myriad of functions, including welding, painting, and assembly operations, with unparalleled precision and speed. By incorporating robotics into the assembly line, manufacturers are able to significantly reduce the time required to build an electric vehicle, thereby boosting overall production rates. Additionally, the use of robotics minimizes the margin of error, leading to a higher standard of quality and reliability in the final product.