The rise of electric vehicles (EVs) has revolutionized the automotive industry, with more drivers opting for sustainable and eco-friendly transportation options. However, behind the sleek and energy-efficient exteriors of EVs lies a complex and meticulous assembly process. In this article, we will provide a step-by-step guide to the electric vehicle assembly process, shedding light on the intricate procedures involved in bringing these cutting-edge vehicles to life.

Step 1: Component Manufacturing and Assembly

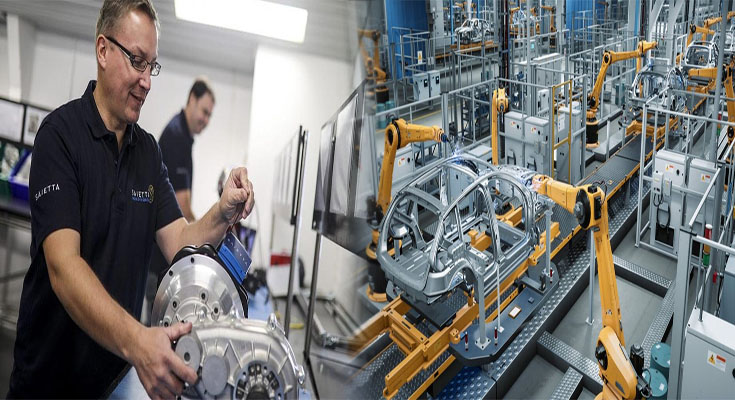

The first stage of the electric vehicle assembly process begins with the manufacturing of essential components such as the battery pack, electric motor, and power electronics. These components are meticulously engineered to ensure optimal performance and efficiency. Once the components are ready, they are assembled into a drivetrain system.

Step 2: Chassis Integration

The next step in the assembly process involves integrating the drivetrain system into the vehicle chassis. This includes connecting the battery pack to the electric motor and installing other key components such as the suspension system, braking system, and steering mechanism. The chassis serves as the structural foundation of the vehicle, providing support and stability.

Step 3: Body Assembly and Exterior Finishing

Once the chassis integration is completed, the body of the electric vehicle is assembled. This includes attaching exterior panels, doors, windows, and other aesthetic components. The exterior finishing process involves painting, polishing, and detailing the vehicle to achieve a flawless and visually appealing finish.

Step 4: Interior Installation

After the body assembly is finished, the focus shifts to installing the interior components of the electric vehicle. This includes fitting the dashboard, seating, entertainment systems, and other comfort features. The interior design is carefully crafted to ensure a stylish, ergonomic, and user-friendly driving experience.

Step 5: Quality Control and Testing

Before an electric vehicle is deemed ready for the market, rigorous quality control checks and testing procedures are conducted. Various tests, such as performance testing, safety testing, and durability testing, are carried out to ensure that the vehicle meets the highest standards of quality and reliability.

Step 6: Final Inspection and Packaging

The final step of the electric vehicle assembly process involves a comprehensive inspection to verify that all components are correctly installed and functioning as intended. Once the vehicle passes the final inspection, it is meticulously cleaned, packaged, and prepared for shipment to dealerships or directly to customers.

The assembly process of electric vehicles is a sophisticated and intricate undertaking that requires precision, expertise, and attention to detail. By following this step-by-step guide, we have provided insight into the meticulous procedures involved in bringing electric vehicles from concept to reality. As the global demand for sustainable transportation continues to grow, the electric vehicle assembly process will play a crucial role in shaping the future of the automotive industry.