The Diesel engine was created by Rudolf Diesel in response to the fuel inefficiency of gasoline engines. This is power to the piston crowns, not to the drive shaft of whatever you are powering with it. Since you have additional piston rings, crank shafts, conrods and whatnot, you are in truth losing more energy in friction than you would be in a single piston engine. The opposed piston engine can also be modified to function as a four-cycle engine by providing each intake and exhaust valves which are timed at chosen positions through the crankshaft rotations.

The phase shift of the two shafts may well also be achieved by other mechanisms, not shown, which can be adjusted even though the engine is in operation. EM’s opoc® engine does not have a cylinder head or valve train, which are the sources of a lot of the airborne and structure borne noise from standard engines. Some variations of the opposed piston or OP styles use a single crankshaft The Gobron-Brillié , five and Doxford ship engines six used a crankshaft at one particular finish of the cylinders and a crosshead for the opposing piston.

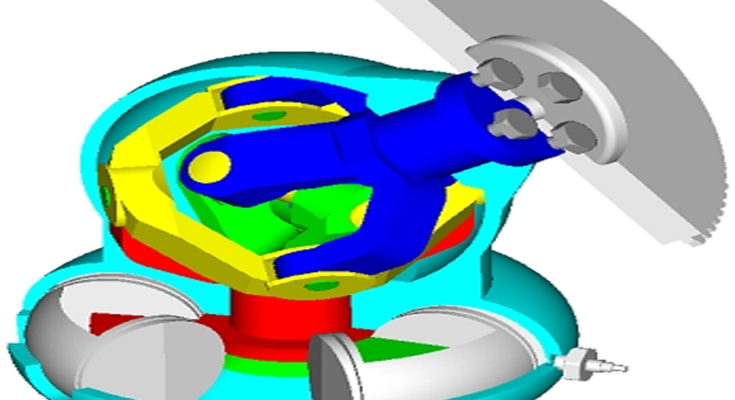

One more object of the invention is to supply a novel and improved omnitorque opposed piston engine which could be operated as a compressed air engine, a steam engine or as an internal combustion engine of either the two or four cycle form. In an opposed piston (op) engine, each and every piston travels about half the distance of a piston in a traditional engine, and travels at about half the speed. If you double the piston region, you are doubling the loss of pressure throughout the power stroke, simply because you are operating with three dimensions. Therefore, the air-fuel inflow into the piston have to be arranged to scavenge the exhaust.

A principal object of the invention is to provide an novel and enhanced opposed piston engine, wherein the rotation of 1 crankshaft is phased to lag the rotation of the other by about 90 degrees to boost the operative, cyclic action of the prime mover gas inside the cylinder chambers in between the pistons and to an improved sustained torque output with a substantial reduction in vibration creating effects.

Every single crankshaft carries a connecting rod 41 which connects with its respective major piston 43 and secondary piston 44. In accordance with traditional twocycle engine style, the inlet port 45′ and exhaust port 46 operate simultaneously, at the bottom dead center position of the principal piston, and with these ports becoming diametrically opposed.