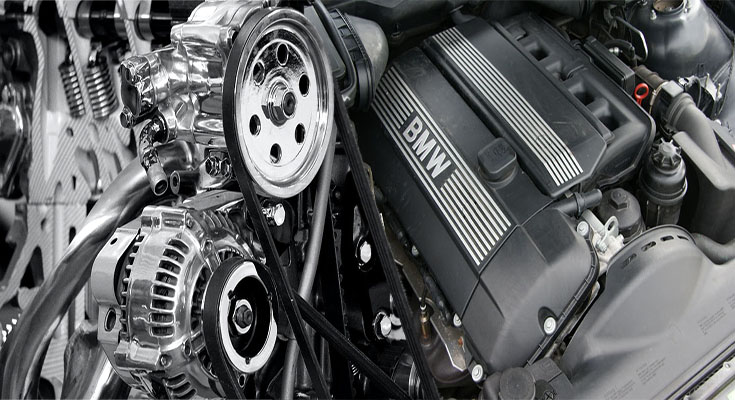

5 Essential Car Engine Parts and Functions

A car’s engine is composed of around 200 parts. Knowing how each of them works is essential for maintaining your car’s longevity. Here are 5 essential parts of your car’s engine that you should know. Understanding how these parts work will help you know what’s wrong with your car, and can help you find a reputable mechanic who can repair it properly. Also, keep in mind that not all of these parts are the same.

Oil pan

The oil pan in a car engine is an integral part of the vehicle’s engine. It holds six liters of oil and is designed to fit snugly into the vehicle’s available space near the chassis and steering gear. The oil pan is also designed with ribs to reduce turbulence and improve stiffness of the flat section. In addition, it features warm-embossed brass inserts to accommodate the oil level switch and discharge screw.