The heart of any electric vehicle (EV) lies in its battery, which powers the vehicle and determines its driving range and performance. The assembly process of electric vehicle batteries is a critical and meticulous procedure that involves several key stages to ensure the production of high-quality and efficient batteries. In this article, we will explore the key stages of the electric vehicle battery assembly process, shedding light on the intricate steps involved in creating the power source of EVs.

1. Cell Manufacturing

The first stage of the electric vehicle battery assembly process is cell manufacturing. Battery cells are the building blocks of the battery pack and are typically produced using advanced manufacturing techniques. This stage involves the production of lithium-ion cells, which are the most commonly used type of cells in EV batteries. The cells are manufactured with precision to ensure uniformity and reliability.

2. Cell Testing and Sorting

Once the battery cells are manufactured, they undergo rigorous testing to assess their performance and quality. Cells that meet the specified criteria are sorted based on their capacity, voltage, and internal resistance. This sorting process ensures that only cells with consistent characteristics are used in the battery pack, which is essential for optimizing the performance and longevity of the battery.

3. Module Assembly

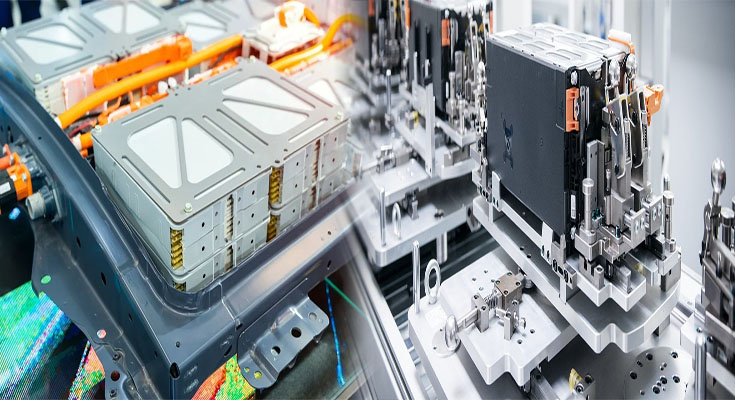

After the cell testing and sorting stage, the next key stage is module assembly. Battery modules are assemblies of multiple cells that are interconnected to increase the voltage and capacity of the battery pack. The modules are typically arranged in a specific configuration to maximize energy density and efficiency. The module assembly process involves connecting the cells, adding thermal management components, and ensuring proper insulation and safety measures.

4. Pack Assembly

The final stage of the electric vehicle battery assembly process is pack assembly. Battery packs are the complete assemblies that house the battery modules and provide the power source for the electric vehicle. The pack assembly process involves stacking the modules, connecting them in series and parallel configurations, and integrating the electronic components for monitoring and control. The pack is then enclosed in a protective casing and undergoes rigorous testing to validate its performance and safety.

5. Quality Control and Testing

Throughout each stage of the electric vehicle battery assembly process, quality control and testing are paramount. Various tests, including electrical performance testing, thermal testing, and safety testing, are conducted to ensure that the battery pack meets the stringent quality standards required for automotive applications. Any deviations or issues identified during testing are rectified to ensure the reliability and safety of the battery pack.

The electric vehicle battery assembly process is a sophisticated and highly regulated procedure that involves several key stages to produce high-performance and reliable battery packs for electric vehicles. By understanding the intricacies of each stage, we gain insight into the technology and precision required to manufacture the power source that drives the sustainable future of transportation.