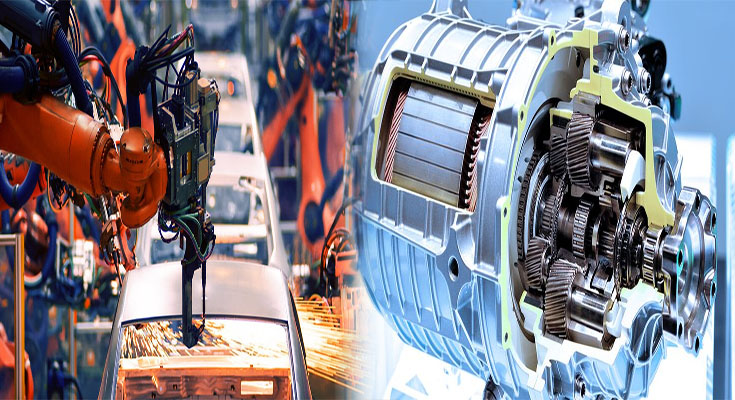

The assembly of electric vehicle (EV) motors and drivetrains involves a sophisticated and meticulous process that is integral to the performance and efficiency of electric vehicles. From the production of electric motors to the integration of drivetrain components, every step in the assembly process is crucial to ensuring the seamless operation of EVs. In this article, we will delve into the electric vehicle motor and drivetrain assembly process in detail, shedding light on the intricacies of assembling the essential components that power electric vehicles.

Electric Motor Manufacturing

The first stage of the assembly process involves the manufacturing of the electric motor, which serves as the primary propulsion system of the electric vehicle. Electric motors are typically produced using advanced techniques such as precision machining and assembly to ensure optimal performance and efficiency. This stage also involves the production of components such as the rotor, stator, and housing, which are carefully crafted to exact specifications.

Motor Testing and Validation

Once the electric motor is manufactured, it undergoes rigorous testing and validation to verify its performance and quality. Various tests, including electrical efficiency testing, thermal testing, and durability testing, are conducted to ensure that the motor meets the stringent standards required for automotive applications. Any deviations or issues identified during testing are addressed to ensure the reliability and longevity of the motor.

Inverter and Power Electronics Assembly

In parallel to motor manufacturing, the inverter and power electronics components are assembled. The inverter is responsible for converting the direct current (DC) from the battery pack into alternating current (AC) to drive the electric motor. The assembly process involves integrating electronic components such as insulated gate bipolar transistors (IGBTs) and capacitors to create a robust and efficient power conversion unit.

Transmission and Drivetrain Integration

The assembly process also involves the integration of the transmission and drivetrain components. In an electric vehicle, the drivetrain transfers power from the electric motor to the wheels, and the transmission helps in optimizing the speed and torque delivery. This stage involves the alignment and installation of gears, shafts, and bearings to ensure smooth power transmission and efficient operation.

Motor and Drivetrain Integration

Once the electric motor, inverter, and drivetrain components are manufactured and tested, they are integrated into the vehicle chassis. This phase involves mounting the motor, inverter, and drivetrain onto the structural frame of the vehicle, and connecting them to the wheels and suspension system. The integration process is critical in aligning the components properly and ensuring optimal performance and reliability.

Quality Control and Testing

Quality control and testing are paramount in the electric vehicle motor and drivetrain assembly process. Each integrated component undergoes a series of tests, including dynamic testing, load testing, and efficiency testing, to verify its performance and compliance with industry standards. Additionally, the entire drivetrain assembly is subjected to rigorous testing to ensure seamless operation and safety.

The assembly process of electric vehicle motors and drivetrains is a multi-faceted and intricate procedure that demands precision, expertise, and adherence to quality standards. By understanding the detailed stages involved in assembling the essential components of electric vehicles, we gain insights into the advanced technology and engineering excellence required to create the powertrain systems that drive the sustainable future of transportation.