Accelerating the Future: Latest Innovations Shaping the Modern Car Development Process

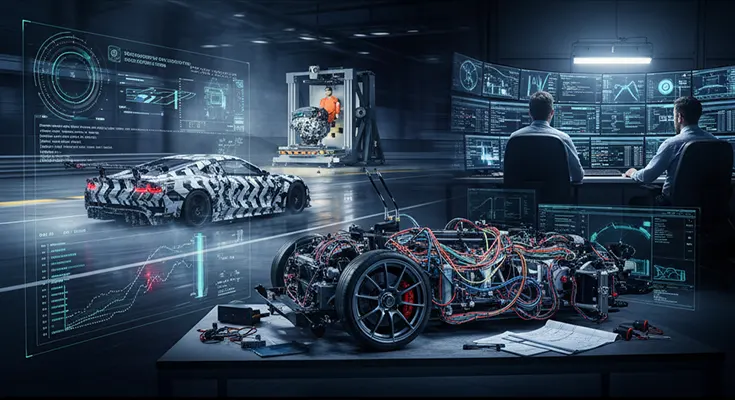

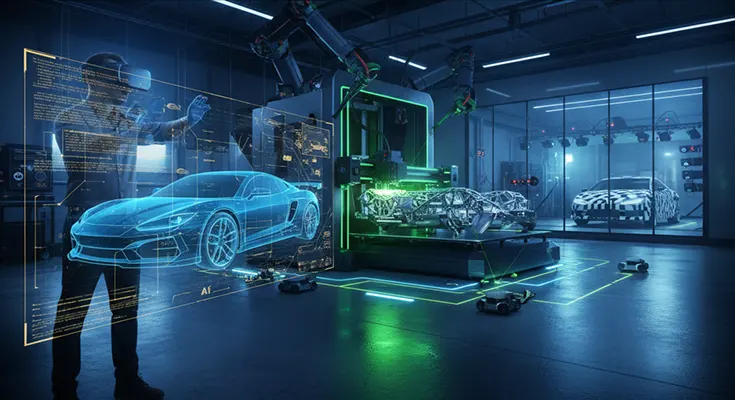

The modern automotive industry is in the midst of a profound revolution. The shift is no longer just about horsepower and sheet metal; it’s about software, data, and sustainable processes. The traditional, multi-year, physical prototyping process is being rapidly replaced by agile, digital-first methodologies.

These latest innovations shaping the modern car development process are transforming vehicles into “Software-Defined Vehicles” (SDVs) and factories into intelligent, interconnected ecosystems.Here are the key trends driving the new era of automotive development.

1. The Rise of the Software-Defined Vehicle (SDV)

The most significant change is the recognition that the car is now a high-powered computing platform. This changes the focus of development from hardware to software.

- Over-the-Air (OTA) Updates: Borrowed from the consumer electronics world, OTA updates allow manufacturers to deploy new features, performance improvements, security patches, and even recalls remotely. This radically shortens the development cycle, allowing for continuous refinement even after the vehicle