CELERIFERE the initially car absolutely free from animals knows as the 1st generation bicycle paved way for series of new discoveries major modern day cycles. History of the Assembly Line : A brief summary of the use of the assembly line in the meatpacking industry, and of its later presence in the auto market. In an assembly line, car assembly is split among a number of stations, all functioning simultaneously. Meat Packing : A brief discussion of factory workers and assembly lines in today’s meatpacking business. In the early days of automobile production, competitors for production line workers was fierce, and auto businesses offered – or were forced to offer you by worker’s unions – generous pay.

CELERIFERE the initially car absolutely free from animals knows as the 1st generation bicycle paved way for series of new discoveries major modern day cycles. History of the Assembly Line : A brief summary of the use of the assembly line in the meatpacking industry, and of its later presence in the auto market. In an assembly line, car assembly is split among a number of stations, all functioning simultaneously. Meat Packing : A brief discussion of factory workers and assembly lines in today’s meatpacking business. In the early days of automobile production, competitors for production line workers was fierce, and auto businesses offered – or were forced to offer you by worker’s unions – generous pay.

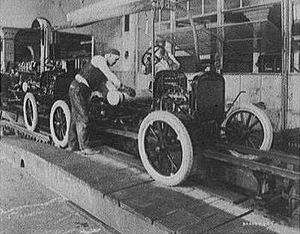

Consequently, considerable adjustments have been created to the creating to accommodate the assembly line’s needs. Ford did not conceive the notion, he perfected it. Prior to the introduction of the assembly line, vehicles have been individually crafted by teams of skilled workmen – a slow and expensive procedure. The Venetian Arsenal , dating to about 1104, operated equivalent to a production line. As much more and much more machines had been becoming invented and applied all about the nation, folks continued seeking for methods to improve productivity.

Henry Ford Creates the First Assembly Line : A web page that discusses Henry Ford’s implementation of the assembly line, and how it revolutionized his sector and all others. Instead of workers going to the car or truck, the auto came to the worker who performed the same job of assembly more than and over again. As new assembly line strategies are introduced into manufacturing processes, company managers look at the techniques for achievable application to other areas of small business.

A automobile would arrive at the station, and the worker would execute the specified task – more than and over once again on every single auto that came by. Due to the fact each worker had 1 job and worked on just 1 car or truck at a time, it meant that hundreds of automobiles had been being constructed simultaneously all through the factory.

Actually it took 4 years and more to create Model T. Previous models were the guinea pigs, a single may say, for experimentation and improvement of a auto which would realize Henry Ford’s dream of a car which everyone could afford to get, which anyone could drive anyplace, and which almost anyone could maintain in repair. Getting the product come to the worker and assigning the worker to perform the similar task on every vehicle produced production a lot additional effective and brought the cost of creating the vehicles down, as well.