As the demand for electric vehicles (EVs) continues to rise, manufacturers are constantly seeking ways to optimize the assembly process for efficiency. One of the key strategies that has proven to be highly effective is the integration of automation technologies. Automation in the electric vehicle assembly process not only streamlines production but also improves quality, reduces lead times, and minimizes overall costs.

Streamlining Production with Robotics

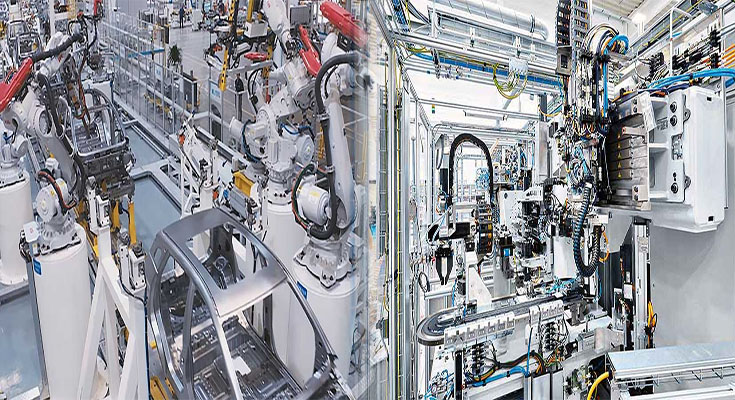

Robotic systems are integral to automation in the electric vehicle assembly process. These systems can perform a myriad of functions, including welding, painting, and assembly operations, with unparalleled precision and speed. By incorporating robotics into the assembly line, manufacturers are able to significantly reduce the time required to build an electric vehicle, thereby boosting overall production rates. Additionally, the use of robotics minimizes the margin of error, leading to a higher standard of quality and reliability in the final product.

Advanced Material Handling Systems

Efficient material handling plays a crucial role in the assembly process of electric vehicles. Automation in this area involves the use of advanced conveyor systems, automated guided vehicles (AGVs), and robotic arms for material transfer and positioning. These systems enable a seamless flow of components and parts along the assembly line, reducing congestion and optimizing the use of space. As a result, the entire manufacturing process becomes more efficient, with minimal downtime and improved accuracy in component placement.

Precision Assembly with Automated Bolting and Fastening

The precision required in fastening and bolting operations demands a high level of accuracy and repeatability. Automation technologies, such as automated fastening systems and robotic torque wrenches, ensure the consistent and uniform application of torque, eliminating the risk of over-tightening or under-tightening. This not only enhances the structural integrity of the assembled components but also contributes to a more stringent and reliable assembly process.

Real-time Monitoring and Quality Control

Automation facilitates real-time monitoring and quality control in the electric vehicle assembly process. Sensor-based systems and machine vision technology are employed to detect defects, measure tolerances, and verify the integrity of assembled components. Any deviations from the specified parameters can be immediately addressed, ensuring that only high-quality components proceed to the next stage of assembly. This proactive approach to quality control minimizes rework and maximizes productivity.

The Future of Efficiency in EV Manufacturing

As electric vehicle technology advances, the role of automation in the assembly process will continue to evolve. The implementation of smart manufacturing concepts, such as the integration of artificial intelligence and predictive maintenance, will further enhance the efficiency and reliability of EV production. With automation at the forefront, manufacturers are positioned to meet the growing demand for electric vehicles while maintaining high standards of quality and operational excellence.

Automation in the electric vehicle assembly process is a key enabler of efficiency, offering numerous benefits to manufacturers, including streamlined production, precision assembly, and real-time quality control. As the automotive industry transitions towards electrification, the adoption of advanced automation technologies will be pivotal in sustaining a competitive edge and meeting the dynamic demands of the market.