Electronic fuel injections are a method which enables fuel into a central combustion engine, electronic fuel injection systems break up the fuel by powerfully pushing it through a tiny syringe beneath a extremely high stress. Porsche continued working with this method on its racing vehicles into the late seventies and early eighties. With the implementation of the national IV emission common, as the most appropriate technology roadmap, prevalent rail system for diesel engines witnessed speedy improvement. Engine mechanical describes installation and removal of these components: drive belt tension, auto tensioner, ignition timing belt, idle speed and mixture, compression pressure, manifold vacuum, lash adjuster, crankshaft pulley, camshaft and valve stem seal, oil pan, crankshaft oil sea, timing belt and engine assy. Wide functionality and hassle-free quantity of I/ for optimal engine operation and monitoring.

Electronic fuel injections are a method which enables fuel into a central combustion engine, electronic fuel injection systems break up the fuel by powerfully pushing it through a tiny syringe beneath a extremely high stress. Porsche continued working with this method on its racing vehicles into the late seventies and early eighties. With the implementation of the national IV emission common, as the most appropriate technology roadmap, prevalent rail system for diesel engines witnessed speedy improvement. Engine mechanical describes installation and removal of these components: drive belt tension, auto tensioner, ignition timing belt, idle speed and mixture, compression pressure, manifold vacuum, lash adjuster, crankshaft pulley, camshaft and valve stem seal, oil pan, crankshaft oil sea, timing belt and engine assy. Wide functionality and hassle-free quantity of I/ for optimal engine operation and monitoring.

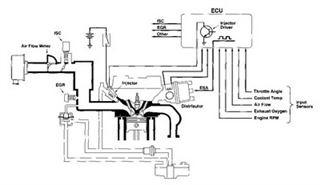

Far more precise management of the fuel injection occasion also enables far better manage of emissions. Later Closed loop fuel injection systems improved the air/fuel mixture control with an exhaust gas oxygen sensor Despite the fact that not portion of the injection control, a catalytic converter further reduces exhaust emissions. This was made to meet the U.S. emission specifications with no loss in efficiency and it also lowered fuel consumption. The duration that the injector is open (known as the pulse width ) is proportional to the amount of fuel delivered.

Fuel injection was phased in through the latter 1970s and 80s at an accelerating rate, with the German, French, and U.S. markets top and the UK and Commonwealth markets lagging somewhat. Made in China 2025, released by China in Might 2015, mentioned that the Government will press ahead with the application of diesel engines in passenger vehicles.

Citation required The principal difference amongst carburetors and fuel injection is that fuel injection atomizes the fuel via a smaller nozzle under high pressure, while a carburetor relies on suction made by intake air accelerated through a Venturi tube to draw the fuel into the airstream. When signalled by the engine manage unit the fuel injector opens and sprays the pressurised fuel into the engine.

In the 1990s, it was widespread to program engine controllers to adjust injection timing to optimize fuel consumption in heavy-duty diesel engines when the operating circumstances indicated highway cruise situations. With their incredibly fast response time, numerous injection events can occur for the duration of each and every cycle of each and every cylinder of the engine. Improved mechanical efficiency of the injection technique to contribute to the all round aim of enhancing engine efficiency.