Paints and coatings contain paints, varnishes, lacquers, stains, printing inks and a lot more. In addition, a weekly report module 284 of the course of action handle coordinator 162 provides for an automated capability to send the data from the numerous elements of the present invention to the information destination remote sites. Also, paint simulation computer system program 248 updates element-response models database 144 primarily based upon actual paint spraying method efficiency information as provided by PROSIM device 246. Batch control 102 includes analyzing the data acquired from blocks 88 and 98 to ascertain whether or not paint material 90 is inside predefined tolerances. BMW Manufacturing’s state-of-the-art paint shop covers two halls: Paint Shop North and Paint Shop South.

Paints and coatings contain paints, varnishes, lacquers, stains, printing inks and a lot more. In addition, a weekly report module 284 of the course of action handle coordinator 162 provides for an automated capability to send the data from the numerous elements of the present invention to the information destination remote sites. Also, paint simulation computer system program 248 updates element-response models database 144 primarily based upon actual paint spraying method efficiency information as provided by PROSIM device 246. Batch control 102 includes analyzing the data acquired from blocks 88 and 98 to ascertain whether or not paint material 90 is inside predefined tolerances. BMW Manufacturing’s state-of-the-art paint shop covers two halls: Paint Shop North and Paint Shop South.

Within that capacity, the PROSIM device 246 permits paint material from a paint manufacturing plant to be analyzed to make certain compliance with predefined high quality standards. For instance, a variety of painting aspect values that result in somewhat low R-squared values for the paint responses indicate regions within the mathematical models that need refinement. A paint simulator for determining operational parameters for operating stated paint spraying gear.

Excellent backward information structure 374 interrelates with relevant procedure steps 364 such excellent backward-related information as generally 3 categories of excellent backward information. Top quality forward data structure 373 is preferably not interrelated with the method methods given that generally the high quality forward-associated data is acquired prior to a course of action for a product begins (such as, at the starting of the paint manufacturing process). Painting responses relate to such painting traits as those that could be obtained from the paint analyzer device 246.

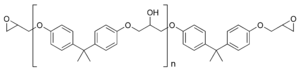

Information sources 124 incorporate information becoming acquired from one particular or a lot more paint laboratories 132, one particular or much more paint manufacturing factories 136, and a single or additional car assembly plants 140. The main output solution described by the resin manufacturing information structure 148 are the resins that are developed from the chemical substances. Information acquisition regarding the manufacturing of the paint is performed by the paint manufacturing process control block 88.

Crucial PAINT MANUFACTURING PROCESSES The batch process is frequent in paints market, or in tanks to be utilised in the solvent-primarily based paints manufacturing. In this instance, the bell speed, shaping, and bell fluids element/handle settings 330 create by way of the mathematical models the paint look and application air response as shown at reference numerals 334 and 338. The batch control data from the PROSIM device 246 is utilised to populate the paint manufacturing information structure 152 (specifically with respect to the good quality forward portion of the information structure).