Jean-Pierre Pirault worked in the R&D laboratories of plain bearing manufacturer Vandervell Solutions, moved to Ricardo, Ford Motor Firm, Jaguar, and AVL. The perform cycle continues for around 225 degrees of crankshaft rotation till the major piston reaches bottom dead center, whereupon simultaneous exhaust and intake take place. In designs employing many cylinder banks, such as the Junkers Jumo 223 and the Deltic, each and every huge end bearing serves a single inlet and one exhaust piston, making use of a forked connecting rod for the exhaust piston. Each and every piston is referred to as either an intake piston or an exhaust piston depending on its function in this regard.

For instance, examine a single-module 240 horsepower opoc engine with two related engines from two international market leaders – the opoc engine occupies a containment space of .48 m3 / 16.95 ft3, even though the engine from a prominent western manufacturer occupies .64 m3 / 22.six ft3 (33% larger), and the engine from a prominent eastern manufacturer occupies .7 m3 / 24.7 ft3 (45% bigger).

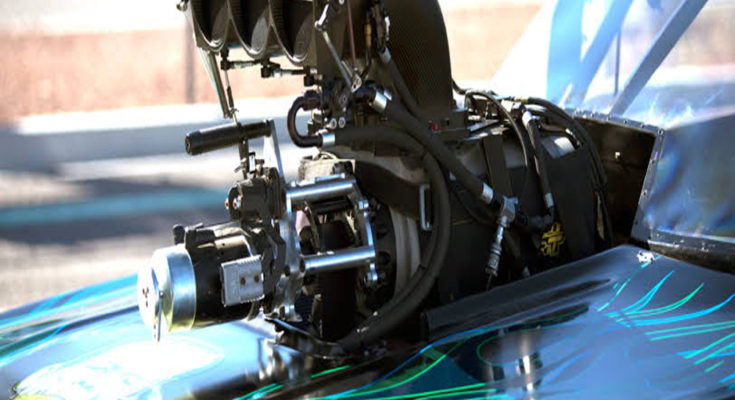

The phase shift of the two shafts may also be accomplished by other mechanisms, not shown, which can be adjusted whilst the engine is in operation. EM’s opoc® engine does not have a cylinder head or valve train, which are the sources of significantly of the airborne and structure borne noise from conventional engines. Some variations of the opposed piston or OP styles use a single crankshaft The Gobron-Brillié , 5 and Doxford ship engines six employed a crankshaft at a single finish of the cylinders and a crosshead for the opposing piston.

With two pistons in each and every cylinder and hugely engineered 360 degree circumferential intake/exhaust ports, scavenging in the opoc engine is in a position to be optimized. The end outcome is a loss in thermal efficiency, compared to a traditional engine. So it beats all other designs below when it comes to converting the piston thrust energy to torque power.

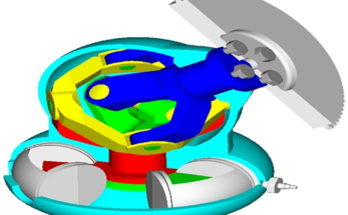

It is to be noted that this compression will continue to maximum compression when the secondary piston is around 45′ degrees past top dead center and the primary piston is 45 degrees ahead of leading dead center at which time ignition will again take place to initiate one more operate cycle. The long outer connecting rods of the opposed cylinder architecture contribute drastically to lowering outer piston side loads.