How to Build Sports Cars

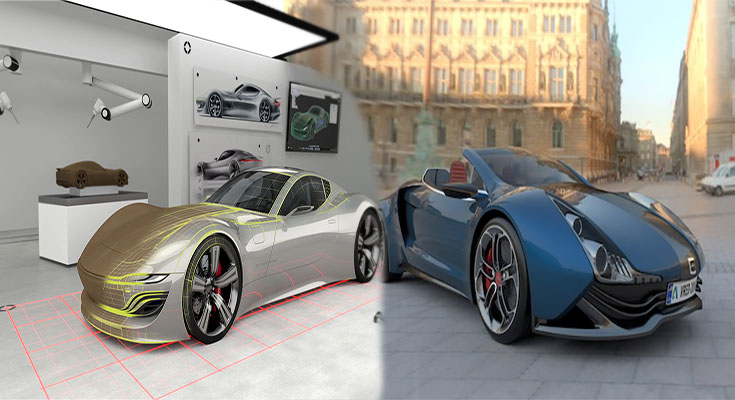

Replica building a sports car can have many advantages. It can be a fun project for a family to work on together, and if you enjoy mechanical projects, replica building is an ideal way to pursue them. Replica building requires a kit body and a commonly available mainstream automotive base, and can provide hours of fun. Below are some tips for starting your replica building project. Listed below are some examples of successful sports cars that were built by amateurs.

Ken’s sports car took him 17 years to build

When Ken Imhoff was building his custom Lamborghini Countach, he was not content with a replica. He also wanted to be unique, so he went all out, constructing a tubular space-frame chassis and aluminum body panels. He even added a Corvette C4 suspension kit to the car. It took 17 years to build his sports car from the ground up.